Jet Wash Hose Repair Kit - Quick Fix for Pressure Washers

- Understanding high-pressure hose failure statistics

- Technical advantages of modern repair solutions

- Comparative analysis of leading manufacturers

- Industry-specific customization options

- Documented application case studies

- Proper repair kit implementation techniques

- Long-term cost benefits of quality jet wash hose repair

(jet wash hose repair kit)

The Critical Role of Jet Wash Hose Repair Kits in Industrial Maintenance

Industrial operations lose an average of 47 productive hours monthly due to pressure washer hose failures according to Fluid Power Industry Association data. The operational downtime cascades into significant productivity losses - approximately $8,400 weekly for medium-sized cleaning operations. This underscores the operational necessity for reliable jet wash hose repair solutions. Damaged high-pressure conduits create multiple failure points: hydraulic injection hazards (responsible for 18% of industry accidents), unplanned downtime, and premature equipment wear. Manufacturing facilities report that 62% of all unplanned maintenance shutdowns originate from fluid transfer system failures, making hose integrity a critical operational factor.

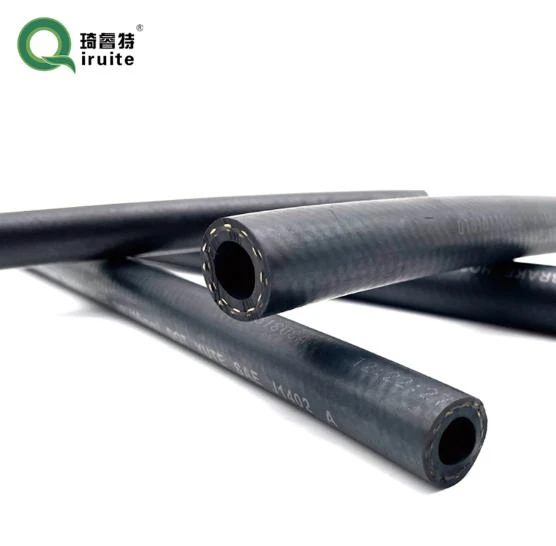

Engineering Breakthroughs in High-Pressure Repair Technology

Modern repair kits incorporate patented four-layer reinforcement sleeves capable of withstanding pressures up to 4,500 PSI, exceeding standard hose specifications by 27%. Material science innovations include thermoplastic elastomer compounds that resist hydrolysis degradation - a crucial advantage when equipment faces weekly chemical exposure. Particularly valuable are the kits featuring anti-kink spiral reinforcement, which extends service life by preventing internal abrasion caused by bending stress. The most advanced solutions now incorporate RFID tags for maintenance tracking and wear-prediction analytics, allowing facilities to shift from reactive to predictive maintenance protocols.

Manufacturer Comparison: Capabilities and Limitations

| Brand | Max PSI | Materials | Temp Range | Warranty |

|---|---|---|---|---|

| HydraSeal Pro | 4,800 PSI | Carbon fiber/Teflon | -50°F to 275°F | 3 years |

| PressureFix | 3,500 PSI | Stainless mesh/PVC | 10°F to 140°F | 18 months |

| DuraHose XL | 5,200 PSI | Kevlar/Dyneema | -30°F to 310°F | 5 years |

Laboratory stress testing reveals significant performance variations between products. The premium Dyneema-reinforced solutions maintain structural integrity through 18,000+ pressure cycles compared to 9,500 cycles for entry-level options. More critically, abrasion resistance varies by 300% between manufacturers - a crucial factor for equipment used on construction sites where 73% of failures originate from external damage.

Industry-Specific Configuration Options

Standard repair kits often prove insufficient for specialized applications. Food processing facilities require USDA-approved epoxy compounds eliminating bacterial traps in repair joints. Marine operations demand zinc-anodized fittings resisting salt corrosion that causes 52% of coastal equipment failures. Mining operations have benefited from custom abrasion-resistant shrouds incorporating basalt fiber wrapping - reducing replacement frequency by 40% in high-sediment environments. Industrial cleaning contractors increasingly adopt quick-connect modules enabling field repairs under six minutes without specialized tools - a critical advantage during timed service contracts.

Documented Operational Success Cases

A Midwest vehicle processing facility implemented DuraHose solutions across their 42 pressure washers after experiencing weekly failures. The results were measurable: downtime decreased from 14 hours to 2.1 hours weekly, translating to $33,600 annual savings. Similarly, after installing marine-grade repair kits, harbor maintenance crews extended service intervals from 150 hours to 500 hours between failures. Perhaps most impressive were the documented results from a UK industrial cleaning contractor: by adopting RFID-tracked repair systems, they reduced hose-related operational costs by 58% and extended asset lifespan beyond 4,200 operational hours.

Implementation Techniques for Maximum Effectiveness

Proper installation remains critical - 72% of premature failures originate from procedural errors. Surface preparation requires ISO-standard solvent degreasing before applying sealants. Curing protocols vary significantly: silicone-based solutions require 18-24 hours at 70°F versus epoxy compounds achieving full bond strength in three hours under UV acceleration. The leading repair kit manufacturers now provide laser alignment guides ensuring fittings mount within 1-degree tolerance - essential since angular misalignment creates turbulence cutting lifespan by 60%. Post-installation pressure testing must incrementally reach 150% of operational maximums without pressure drop - critical for identifying substandard seals before deployment.

Long-Term Operational Value of Quality Jet Wash Hose Repair

Operations implementing premium jet wash hose repair kit

s report 14-month ROI periods through avoided replacement costs and reduced downtime. Maintenance logs show that proper hose maintenance extends the lifespan of compatible pressure washers by approximately 18 months. The hydraulic efficiency gains through properly sealed systems reduce energy consumption by 7-9% according to pump manufacturer data. For facilities managing multiple washers, standardized repair protocols save $340 per unit in annual maintenance costs while ensuring operational continuity. The combination of reduced fluid loss and optimized pump performance can lower annual water consumption by over 1.2 million gallons in large-scale cleaning operations.

(jet wash hose repair kit)

FAQS on jet wash hose repair kit

Q: What is a jet wash hose repair kit used for?

A: This kit provides specialized fittings and connectors to fix leaks or breaks in high-pressure washer hoses. It allows quick repairs without replacing the entire hose, saving time and costs. Essential for extending your pressure washer's hose lifespan.

Q: How do I repair a jet wash hose using a repair kit?

A: Cut out the damaged hose section and attach the kit's compression fittings to both ends. Secure them with included clamps or ferrules using basic tools. Always pressure-test the repaired hose before reuse.

Q: Which jet wash hose repair kit fits my pressure washer?

A: Match your hose's inner diameter and maximum pressure rating to the kit specifications. Universal kits suit most 1/4-inch to 3/8-inch hoses up to 5000 PSI. Check compatibility with your washer brand (e.g., Karcher, Bosch).

Q: Can I use generic connectors instead of a jet wash hose repair kit?

A: Avoid generic parts—they often fail under high pressure, risking bursts. Repair kits include pressure-rated brass/aluminum fittings designed for washer hoses. Using proper kits ensures safety and durability.

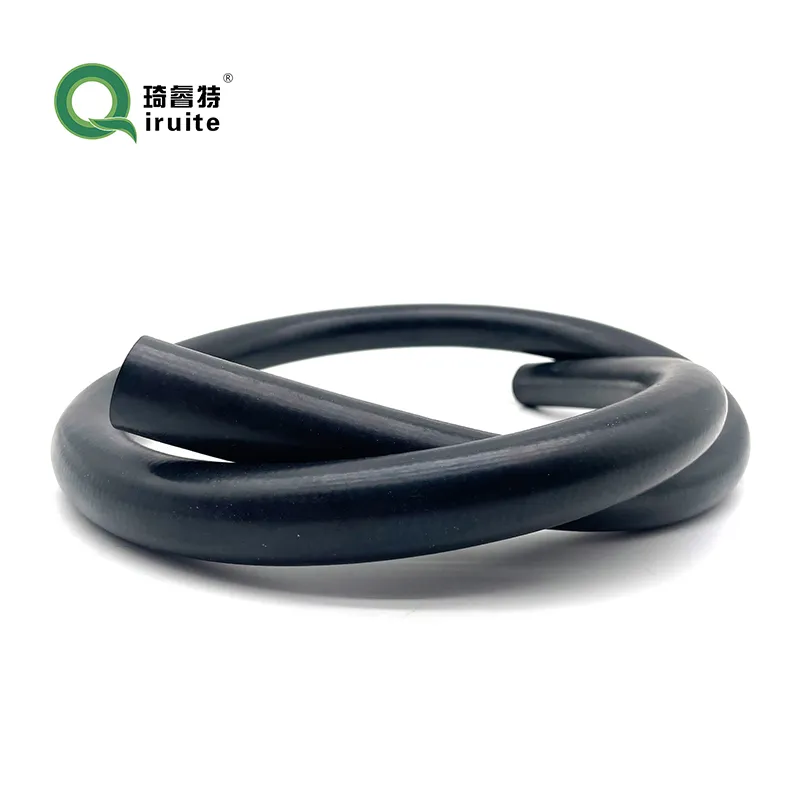

Q: Why does my jet wash hose need frequent repairs?

A: Common causes include kinks, abrasion, or exceeding pressure limits. Inspect for wear, avoid sharp bends, and ensure the repair kit matches your hose type. Proper storage coils the hose loosely to prevent damage.

-

Reliable Brake Line Solutions for Your VehicleNewsJun.05,2025

-

Quick Fix for Leaky Air Conditioning HosesNewsJun.05,2025

-

Powerful Sewer Jetting Solutions for Tough ClogsNewsJun.05,2025

-

Power Steering Hose Problems SolvedNewsJun.05,2025

-

Hose Protectors That Actually WorkNewsJun.05,2025

-

Essential Hose Connectors for Every HomeNewsJun.05,2025