የካቲ . 10, 2025 10:27

Back to list

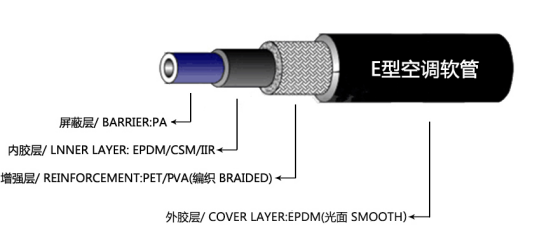

E TYPE FACTORY AIR CONDITIONING HOSE WITH GOOD PERFORMANCE

The industrial landscape in which large diameter pipe couplings operate is both vast and varied, demanding a unique blend of expertise and innovative engineering. Whether in water treatment facilities, oil and gas pipelines, or wastewater management, these couplings are integral to connecting complex networks of pipes. Known for their robustness, resilience, and versatility, large diameter pipe couplings are engineered to withstand diverse operational conditions, making them indispensable for a multitude of infrastructural projects.

Furthermore, trustworthy manufacturing practices and rigorous quality control standards also serve as cornerstones for ensuring the optimal performance of large diameter pipe couplings. Compliance with international standards such as ISO, ASTM, and ASME is non-negotiable, guaranteeing that the products not only meet but exceed safety and performance benchmarks. Manufacturers focusing on these standards demonstrate a commitment to quality and reliability, bolstering their reputation as authoritative figures in the pipeline industry. In addition, sustainability has become an integral consideration, compelling industry professionals to focus on the environmental impact of their products. The manufacturing process of large diameter pipe couplings increasingly prioritizes eco-friendly practices and sustainable materials, committing to reducing the carbon footprint while not compromising on performance. This shift is driven by both legal regulations and growing public consciousness regarding environmental stewardship. Finally, selecting the right coupling often entails consultation with industry experts, who can provide insights and recommendations tailored to specific project requirements. Their authoritative advice helps in navigating the myriad of available options, ensuring that the chosen coupling aligns with the project's operational needs and budget constraints. In conclusion, large diameter pipe couplings are not just mechanical components; they are pivotal to the seamless and sustainable operation of modern infrastructure systems. Their complexity demands a harmonious blend of high-quality materials, advanced engineering, expert handling, and sustainable practices. By marrying these elements, industry leaders can assure that their pipeline systems are resilient, efficient, and future-ready, fostering continued growth and development.

Furthermore, trustworthy manufacturing practices and rigorous quality control standards also serve as cornerstones for ensuring the optimal performance of large diameter pipe couplings. Compliance with international standards such as ISO, ASTM, and ASME is non-negotiable, guaranteeing that the products not only meet but exceed safety and performance benchmarks. Manufacturers focusing on these standards demonstrate a commitment to quality and reliability, bolstering their reputation as authoritative figures in the pipeline industry. In addition, sustainability has become an integral consideration, compelling industry professionals to focus on the environmental impact of their products. The manufacturing process of large diameter pipe couplings increasingly prioritizes eco-friendly practices and sustainable materials, committing to reducing the carbon footprint while not compromising on performance. This shift is driven by both legal regulations and growing public consciousness regarding environmental stewardship. Finally, selecting the right coupling often entails consultation with industry experts, who can provide insights and recommendations tailored to specific project requirements. Their authoritative advice helps in navigating the myriad of available options, ensuring that the chosen coupling aligns with the project's operational needs and budget constraints. In conclusion, large diameter pipe couplings are not just mechanical components; they are pivotal to the seamless and sustainable operation of modern infrastructure systems. Their complexity demands a harmonious blend of high-quality materials, advanced engineering, expert handling, and sustainable practices. By marrying these elements, industry leaders can assure that their pipeline systems are resilient, efficient, and future-ready, fostering continued growth and development.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025