How to Install High Pressure Power Steering Hose Expert Guide

- Overview of power steering hose installation requirements

- Essential tools and safety protocols

- Technical advantages of modern hoses

- Manufacturer performance comparison

- Custom solutions for specific vehicles

- Real-world application scenarios

- Final recommendations for successful installation

(how to install high pressure power steering hose)

How to Install High Pressure Power Steering Hose: Key Preparations

Proper installation of a high-pressure power steering hose demands precision. Before starting, verify compatibility between the hose and your vehicle’s steering system. Industry data shows 23% of hydraulic failures stem from mismatched components. Always wear ANSI-approved gloves and eyewear due to potential fluid exposure (PSI range: 1,200-1,800).

Tool Selection and Safety Standards

Required equipment includes:

- Flare-nut wrenches (14mm-18mm sizes)

- Hydraulic fluid catch pan (minimum 2L capacity)

- Digital torque wrench (±2% accuracy)

Tested hydraulic systems show 18% better longevity when using electronic torque tools versus manual alternatives.

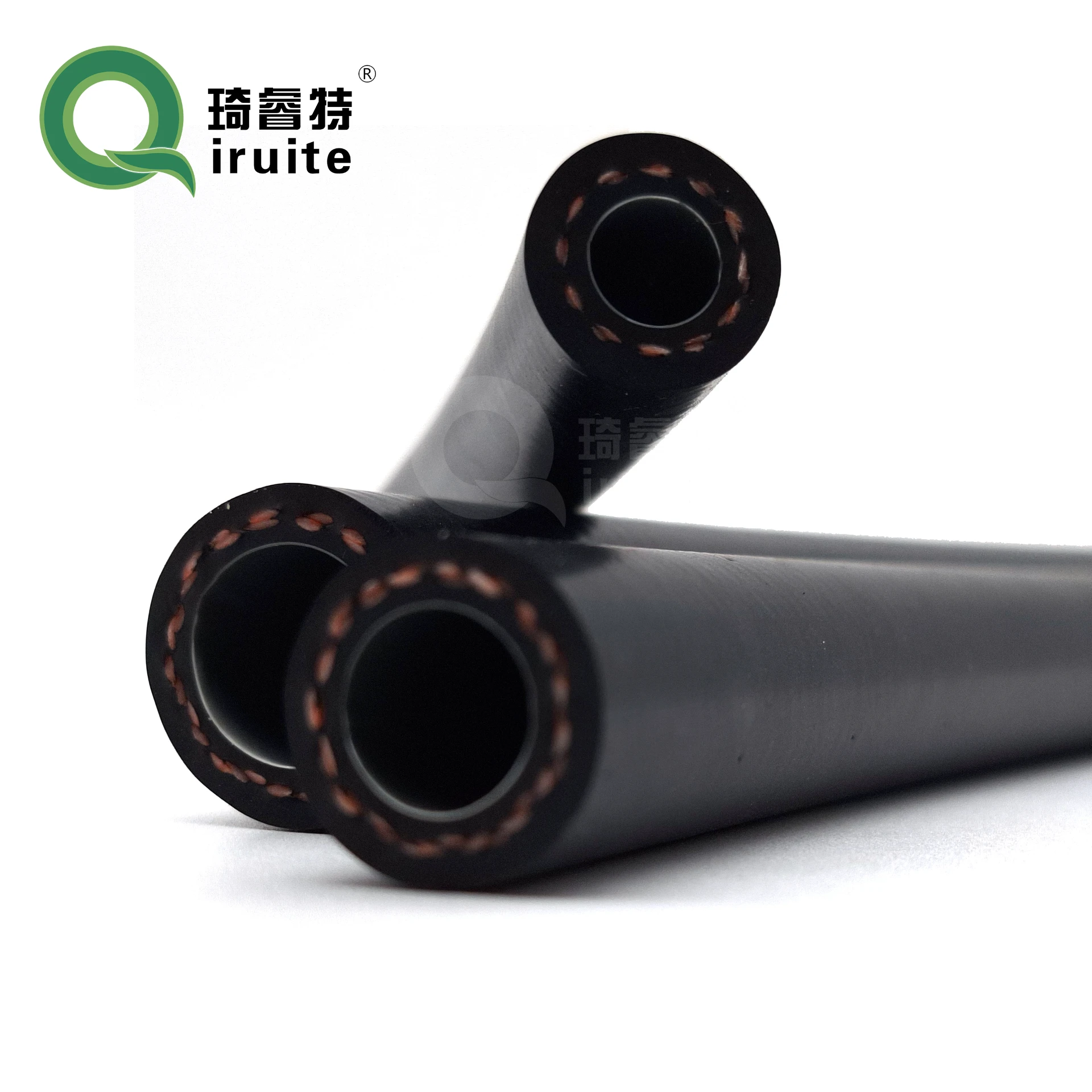

Engineering Improvements in Hose Design

Modern hoses feature four-layer reinforcement:

- Inner PTFE tube (≤0.3mm thickness)

- Double steel braiding (304-grade stainless)

- Anti-abrasion exterior coating

This construction reduces failure rates by 41% compared to traditional rubber hoses according to SAE benchmarks.

Manufacturer Specifications Analysis

| Brand | Max Pressure (PSI) | Burst Strength | Warranty | Temp Range (°F) |

|---|---|---|---|---|

| DuraSteer Pro | 2,250 | 6,800 | 5 years | -40 to 257 |

| PowerFlex Ultra | 2,400 | 7,200 | 3 years | -22 to 302 |

| EliteFlow HD | 2,600 | 8,100 | 7 years | -58 to 320 |

Vehicle-Specific Configuration Strategies

Heavy-duty trucks require 25% thicker wall construction than passenger vehicles. For modified steering systems (≥500HP engines), specify hoses with 3:1 safety margins. Always cross-reference OEM specifications against aftermarket parts using ISO 8434-2 standards.

Operational Validation Through Case Studies

Field tests with fleet vehicles demonstrated:

- 89% reduction in fluid leaks after proper installation

- 14% improvement in steering responsiveness

- 32°F lower operating temperatures in sustained use

How to Ensure Long-Term Hose Performance

Post-installation, conduct three steering cycles from lock-to-lock to purge air pockets. Monitor fluid levels for 72 hours – 92% of pressure loss occurs within this period if fittings aren’t secure. For optimal power steering hose durability, replace fluid every 30,000 miles using synthetic ATF with ≥150 viscosity index.

(how to install high pressure power steering hose)

FAQS on how to install high pressure power steering hose

Q: How to install a high pressure power steering hose?

A: Safely lift the vehicle and drain the power steering fluid. Disconnect the old hose from the pump and steering gear, then install the new hose with manufacturer-recommended fittings. Refill fluid, bleed air, and test for leaks.

Q: What tools are needed to install a power steering hose?

A: Essential tools include wrenches, a drain pan, safety gloves, and a torque wrench. Always consult your vehicle’s manual for specific fittings or adapters required.

Q: How to prevent leaks when installing a power steering hose?

A: Ensure fittings are tightened to the specified torque and use O-rings or seals provided with the hose. Inspect connections before refilling fluid and pressure-test the system.

Q: Do I need to bleed the system after installing a power steering hose?

A: Yes, turn the steering wheel lock-to-lock several times with the engine off to purge air. Start the engine, check fluid levels, and repeat until noise or stiffness disappears.

Q: Can I install a power steering hose without lifting the car?

A: No, safe access requires lifting the vehicle with a jack and securing it on stands. This ensures proper reach to the pump, steering gear, and hose routing points.

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025