የካቲ . 05, 2025 03:34

Back to list

sae j1401 brake hose specifications

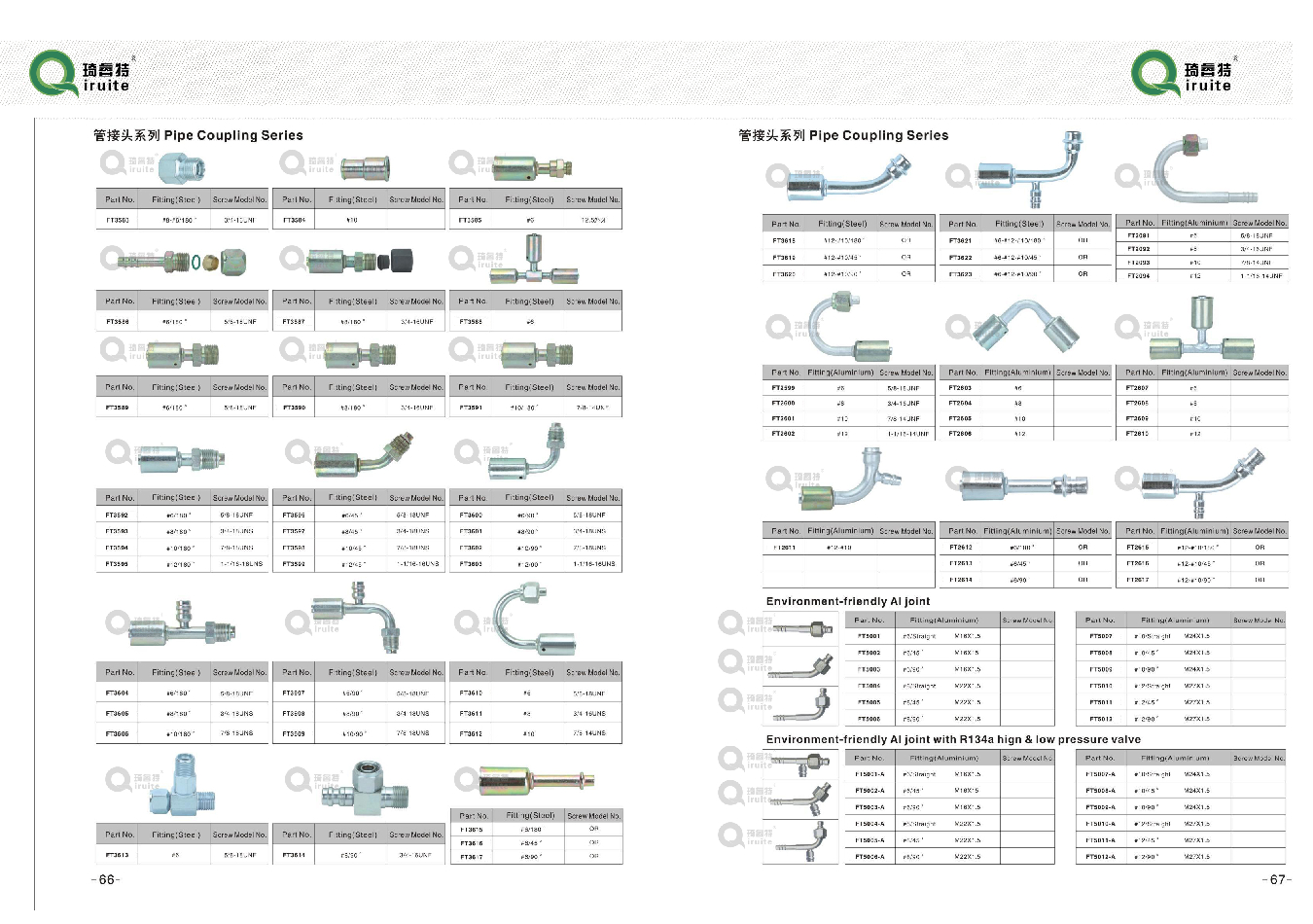

Pipe coupling is a critical component in the plumbing and engineering sectors, specifically for it serves as a connector between two pipes, ensuring fluid or gas conveyance without leaks. In particular, the 7 8 pipe coupling is designed to connect two pipes with a diameter of 7/8 inches, playing a crucial role in various industrial applications.

Highly qualified professionals within the field provide authoritative recommendations for the installation and maintenance of 7 8 pipe couplings. These experts emphasize the importance of proper installation techniques to maximize the performance and lifespan of the couplings. For instance, ensuring that the pipe ends are clean and free of debris is crucial before installation, as this prevents damage to the coupling and the seal during compression. Additionally, using appropriate tools and adhering to torque specifications as prescribed by manufacturers prevent overtightening or under-tightening, which can lead to joint failure. In terms of trustworthiness, 7 8 pipe couplings have earned their reputation through consistent performance and reliability in various applications, from residential plumbing systems to complex industrial networks. End-users and technicians alike trust these components due to their rigorously tested performance under diverse environmental conditions. Manufacturers often provide warranties and certifications to endorse the quality and longevity of their products, further enhancing trust among users who rely heavily on the integrity of piping systems. In conclusion, the significance of 7 8 pipe couplings cannot be overstated within the plumbing and engineering industries. Their impeccable design and construction, endorsed by experienced professionals, make them indispensable for reliable pipe connections. Whether for a new installation or maintenance work, these couplings ensure systems remain leak-free and efficient. Continued advancements in materials and manufacturing techniques promise even greater improvements in durability and performance, maintaining their status as a trusted component in critical applications.

Highly qualified professionals within the field provide authoritative recommendations for the installation and maintenance of 7 8 pipe couplings. These experts emphasize the importance of proper installation techniques to maximize the performance and lifespan of the couplings. For instance, ensuring that the pipe ends are clean and free of debris is crucial before installation, as this prevents damage to the coupling and the seal during compression. Additionally, using appropriate tools and adhering to torque specifications as prescribed by manufacturers prevent overtightening or under-tightening, which can lead to joint failure. In terms of trustworthiness, 7 8 pipe couplings have earned their reputation through consistent performance and reliability in various applications, from residential plumbing systems to complex industrial networks. End-users and technicians alike trust these components due to their rigorously tested performance under diverse environmental conditions. Manufacturers often provide warranties and certifications to endorse the quality and longevity of their products, further enhancing trust among users who rely heavily on the integrity of piping systems. In conclusion, the significance of 7 8 pipe couplings cannot be overstated within the plumbing and engineering industries. Their impeccable design and construction, endorsed by experienced professionals, make them indispensable for reliable pipe connections. Whether for a new installation or maintenance work, these couplings ensure systems remain leak-free and efficient. Continued advancements in materials and manufacturing techniques promise even greater improvements in durability and performance, maintaining their status as a trusted component in critical applications.

Next:

Latest news

-

Ultimate Spiral Protection for Hoses & CablesNewsJun.26,2025

-

The Ultimate Quick-Connect Solutions for Every NeedNewsJun.26,2025

-

SAE J1401 Brake Hose: Reliable Choice for Safe BrakingNewsJun.26,2025

-

Reliable J2064 A/C Hoses for Real-World Cooling NeedsNewsJun.26,2025

-

Heavy-Duty Sewer Jetting Hoses Built to LastNewsJun.26,2025

-

Fix Power Steering Tube Leaks Fast – Durable & Affordable SolutionNewsJun.26,2025