High-Quality Power Steering Tubes: Durable & Leak-Proof Performance

Introduction to High-Quality Power Steering Tubes

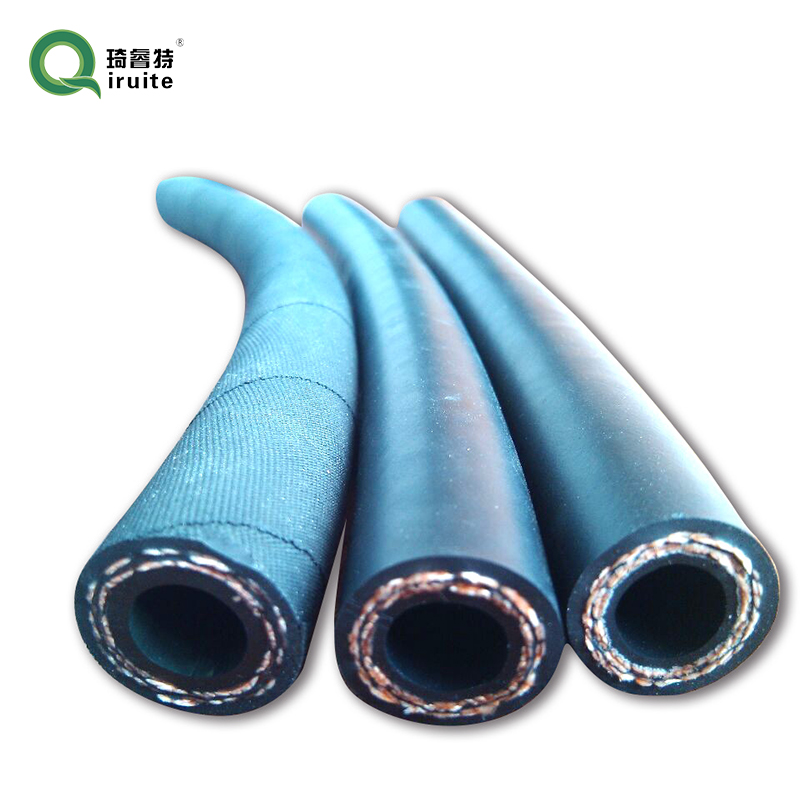

In the intricate hydraulic systems of modern vehicles and heavy machinery, the reliability and performance of every component are paramount. Among these, the Kragstuurbuis van hoë gehalte stands as a critical conduit, responsible for the safe and efficient transfer of hydraulic fluid under extreme pressure. This component ensures smooth, responsive steering, which is vital for operational safety and driver comfort. Our focus in this document is to provide a comprehensive technical overview for B2B decision-makers and engineers, detailing the advanced engineering, rigorous manufacturing, and extensive application potential of these essential tubes.

The performance of a power steering system is directly correlated with the integrity of its tubing. Substandard tubes can lead to system failures, fluid leaks, and ultimately, costly downtime and safety hazards. Therefore, understanding the nuances of material science, manufacturing precision, and strict quality control behind superior power steering tubes is crucial for optimizing system longevity and operational efficiency.

Industry Trends in Power Steering Systems

The automotive and heavy equipment industries are undergoing significant transformations, driven by advancements in technology, stricter environmental regulations, and increasing demands for safety and efficiency. These trends directly impact the design and manufacturing of power steering components, including the Kragstuurbuis van hoë gehalte.

- Shift Towards Electrification: While Electric Power Steering (EPS) systems are gaining traction, hydraulic power steering (HPS) remains prevalent in heavy-duty vehicles, commercial trucks, and many industrial applications due to its robust nature and high force output. Even in hybrid systems, reliable hydraulic components are essential.

- Durability and Longevity: Operators demand components that can withstand harsh operating conditions, extreme temperatures, and corrosive environments. This drives the adoption of advanced materials and surface treatments for enhanced wear and corrosion resistance.

- Noise, Vibration, and Harshness (NVH) Reduction: Engineers are continually seeking ways to minimize NVH. Kragstuurbuis van hoë gehalte designs incorporate features like specialized damping elements and precision bending to mitigate fluid pulsations and structural vibrations.

- Miniaturization and Space Optimization: With increasingly crowded engine bays, there is a constant need for compact, optimized designs that maintain performance. This often involves intricate tube routing and custom bending.

- Material Science Innovations: Research into high-strength, lightweight alloys and advanced polymer coatings is ongoing, aiming to reduce overall vehicle weight, improve fuel efficiency, and extend component life.

- Stringent Safety Standards: Global regulatory bodies continue to impose stricter safety and environmental standards, necessitating robust testing and certification for all steering components.

These trends underscore the critical need for suppliers to not only meet current specifications but also to innovate and provide solutions that anticipate future industry demands for performance, reliability, and cost-effectiveness.

Technical Specifications & Materials

The performance of a Kragstuurbuis van hoë gehalte is fundamentally determined by its material composition and adherence to precise technical specifications. Our tubes are engineered to withstand the demanding conditions of hydraulic systems.

Typical Materials:

- Carbon Steel Alloys: High-strength low-alloy (HSLA) steels like SAE 1010, SAE 1020, or equivalent are commonly used for their excellent tensile strength and fatigue resistance. These are often treated with anti-corrosion coatings.

- Stainless Steel: For applications requiring superior corrosion resistance, such as those exposed to harsh chemicals or marine environments, grades like 304 or 316 stainless steel are preferred.

- Aluminum Alloys: Used in applications where weight reduction is critical, often for return lines or lower-pressure sections, offering good thermal conductivity and corrosion resistance when properly treated.

- Specialized Elastomers/Fluoropolymers: For flexible sections or hoses within the assembly, materials like EPDM, NBR, or FKM are chosen for their resilience to hydraulic fluids, temperature extremes, and chemical degradation.

Critical Technical Parameters:

- Operating Pressure: Typically ranging from 70 Bar (1000 PSI) to 150 Bar (2200 PSI) for standard systems, with burst pressures often exceeding 400 Bar (5800 PSI) to ensure a safety factor of at least 4:1.

- Temperatuurspeling: Designed to perform reliably from -40°C to +120°C, accommodating diverse operational climates and engine bay heat.

- Corrosion Resistance: Achieved through galvanization, zinc-nickel plating, or specialized organic coatings, providing over 400 hours of salt spray resistance (ASTM B117).

- Vibration Fatigue Life: Tubes must withstand millions of vibration cycles at operational frequencies without developing cracks or leaks, validated through rigorous dyno testing to SAE J188 standards.

- Internal Surface Finish: Smooth internal bore is crucial to minimize flow restriction and cavitation, ensuring optimal fluid dynamics and pump longevity.

- Bending Radius: Precision-controlled bending to meet OEM specifications without compromising tube integrity or wall thickness.

These parameters are meticulously controlled throughout the manufacturing process, ensuring that each Kragstuurbuis van hoë gehalte meets or exceeds industry benchmarks for performance and reliability.

Manufacturing Process Flow for High-Quality Power Steering Tubes

The production of a Kragstuurbuis van hoë gehalte involves a multi-stage, precision-engineered process designed to ensure structural integrity, dimensional accuracy, and optimal performance under extreme conditions. Our manufacturing adheres to stringent international standards like ISO 9001 and IATF 16949.

Process Steps:

- Material Selection and Preparation:

High-grade seamless steel tubing (e.g., SAE 1010/1020, DIN 2391/2445) or stainless steel is sourced from certified suppliers. Incoming material undergoes spectrometric analysis and mechanical testing (tensile strength, yield strength, elongation) to verify compliance with specifications.

- Tube Cutting and Deburring:

Tubes are cut to precise lengths using CNC-controlled saws or laser cutting, minimizing material waste and ensuring dimensional accuracy. Ends are meticulously deburred to prevent internal contamination and facilitate subsequent processing.

- Precision Bending (CNC Machining):

Advanced CNC tube bending machines form the tubes into complex geometries with tight tolerances. This process requires precise tooling and programming to avoid kinking, flattening, or excessive wall thinning at bends. Optical scanning ensures conformity to 3D CAD models.

- End Forming and Flaring:

Tube ends are precisely formed (e.g., flaring, swaging, beading) to create secure, leak-proof connections with hydraulic fittings. This often involves cold forming processes that enhance material strength at critical connection points.

- Brazing or Welding (for multi-component assemblies):

Where multiple tube segments or fittings need joining, automated brazing or TIG/MIG welding processes are employed. Weld integrity is verified via visual inspection, dye penetrant testing, or X-ray inspection to ensure no porosity or structural flaws.

- Cleaning and Surface Treatment:

Tubes undergo multi-stage cleaning (e.g., alkaline wash, ultrasonic cleaning, passivation for stainless steel) to remove oils, debris, and contaminants. This is followed by corrosion-resistant coatings, such as zinc-nickel plating (offering >400 hours salt spray resistance per ASTM B117) or epoxy e-coating, applied uniformly for optimal protection.

- Assembly (if applicable):

For complex assemblies, additional components like brackets, isolators, or flexible hose sections are integrated with specialized tooling.

- Rigorous Testing and Quality Control:

Every tube undergoes comprehensive testing:

- Leak Testing: 100% pneumatic pressure testing or hydrostatic pressure testing to specified burst pressures (e.g., 4x working pressure).

- Dimensional Inspection: CMM (Coordinate Measuring Machine) or optical scanning ensures all dimensions, bend angles, and end forms meet tight tolerances.

- Functional Testing: Vibration fatigue testing (SAE J188, J2053), thermal cycling, and pressure pulsation tests simulate real-world conditions to validate service life and reliability.

- Cleanliness Verification: Internal cleanliness tests to prevent contamination of hydraulic systems.

- Packaging and Delivery:

Finished tubes are carefully packaged to prevent damage and contamination during transit, often using protective caps for open ends.

This meticulous process ensures a service life often exceeding 10 years or 150,000 miles in typical automotive applications, significantly reducing maintenance needs and improving overall system reliability. Target industries include automotive OEM, heavy equipment manufacturing, and specialized industrial hydraulic systems where reliable fluid transfer is paramount.

Application Scenarios

The versatile design and robust construction of our Kragstuurbuis van hoë gehalte enable their deployment across a broad spectrum of demanding applications where hydraulic power steering is essential:

- Automotive Passenger Vehicles: Crucial for reliable power steering in sedans, SUVs, and light trucks, ensuring driver safety and comfortable handling. Our tubes meet OEM fitment and performance requirements, contributing to smooth steering response and reduced effort.

- Commercial Trucks and Buses: Essential for heavy-duty steering systems that manage significant vehicle weights and continuous operation. The high pressure and vibration resistance of our tubes extend the service life of these critical components, minimizing costly downtime for fleet operators.

- Construction and Mining Equipment: Used in excavators, loaders, bulldozers, and mining vehicles, where extreme conditions, heavy loads, and abrasive environments demand unparalleled durability and leak-proof performance. Our tubes offer exceptional corrosion resistance and high burst pressure ratings.

- Agricultural Machinery: Tractors, combines, and other farm equipment operate in challenging outdoor conditions. Our tubes provide reliable power steering performance, reducing operator fatigue and increasing productivity in demanding agricultural tasks.

- Material Handling Equipment: Forklifts, reach stackers, and industrial lifts rely on precise hydraulic steering. Our tubes contribute to the safe and efficient operation of these machines in warehouses and logistics centers.

- Specialized Industrial Hydraulic Systems: While primarily focused on power steering, the principles of high-quality fluid transfer for pressure and return lines extend to various industrial hydraulic applications where custom tube assemblies are required for energy-saving and corrosion-resistant fluid conveyance.

In each scenario, the robust design and precise manufacturing of our power steering tubes translate into enhanced operational reliability, reduced maintenance, and improved overall system efficiency.

Technical Advantages

Opting for a Kragstuurbuis van hoë gehalte provides distinct technical advantages that translate directly into superior system performance and lower total cost of ownership (TCO).

- Exceptional Pressure Resistance: Engineered to significantly exceed typical operating pressures, ensuring a substantial safety margin against burst or fatigue failures. This prevents catastrophic fluid leaks and maintains consistent steering performance under peak loads.

- Superior Corrosion Protection: Advanced multi-layer coatings (e.g., zinc-nickel, epoxy) provide unparalleled resistance to road salts, chemicals, and environmental factors. This extends component life, especially in regions with harsh weather or in industrial settings. Our coatings often surpass 1000 hours of salt spray resistance for specific applications, greatly exceeding standard requirements.

- Optimized Vibration Damping: Precision bending and optional integrated damping elements (such as resonance dampeners) are designed to absorb system vibrations and fluid pulsations. This reduces NVH (Noise, Vibration, and Harshness), enhancing driver comfort and preventing premature wear on pumps and racks.

- Enhanced Material Durability: Utilization of high-strength steel alloys or robust stainless steel, combined with meticulous heat treatments, provides excellent fatigue resistance and structural integrity over millions of operational cycles. This translates into a significantly longer service life compared to standard alternatives.

- Precision Dimensional Accuracy: Manufactured with tight tolerances using CNC technology, ensuring perfect fitment and seamless integration with existing hydraulic systems. This eliminates installation issues and potential leak points.

- Leak-Proof Connections: Advanced end-forming techniques (e.g., precise flaring, double-flaring, or O-ring boss connections) create robust, leak-free seals when properly installed with compatible fittings, critical for maintaining hydraulic system integrity and fluid levels.

- High Internal Cleanliness: Tubes are thoroughly cleaned to remove manufacturing residues, preventing contamination of the hydraulic fluid. This protects sensitive components like steering pumps and valves from abrasive wear, extending the life of the entire power steering system.

These advantages collectively contribute to a more reliable, durable, and safer power steering system, directly impacting vehicle uptime and operational costs.

Vendor Comparison: Key Selection Criteria

Selecting the right vendor for Kragstuurbuis van hoë gehalte is a strategic decision that impacts product reliability, supply chain efficiency, and overall cost-effectiveness. Here are critical factors to consider when evaluating potential suppliers:

- Certifications and Compliance:

A reputable vendor should possess certifications such as ISO 9001 (Quality Management Systems), IATF 16949 (Automotive Quality Management System), and demonstrate compliance with relevant industry standards (e.g., SAE J188, ASTM, DIN). This guarantees adherence to strict quality protocols.

- Manufacturing Capabilities and Technology:

Assess the vendor's infrastructure, including advanced CNC tube bending, automated welding/brazing, and specialized coating facilities. Look for evidence of investment in modern machinery and lean manufacturing principles.

- Quality Control and Testing Regimen:

Inquire about their in-house testing capabilities, including hydrostatic burst testing, pulsation fatigue testing, salt spray corrosion testing, and dimensional inspection (CMM). A robust QC process with documented procedures is crucial.

- Material Sourcing and Traceability:

Ensure the vendor uses only high-grade, traceable raw materials from approved suppliers. Transparency in material certification and origin is vital for product integrity.

- Engineering and Design Support:

A strong vendor offers design collaboration, prototyping services, and the ability to reverse-engineer components or develop custom solutions based on specific OEM requirements. Their engineering team should be proficient in CAD/CAM software.

- Lead Times and Supply Chain Reliability:

Evaluate their capacity to meet production volumes, on-time delivery rates, and contingency plans for supply chain disruptions. Flexibility for urgent orders or design changes is a significant asset.

- Customer Support and Warranty:

Responsive customer service, clear warranty terms, and accessible after-sales support are indicative of a reliable long-term partner.

- Cost-Effectiveness vs. Price:

While price is a factor, focus on overall value, considering product quality, longevity, and the potential for reduced warranty claims or operational downtime. A slightly higher upfront cost for a truly high-quality component often yields significant savings over its lifecycle.

Our commitment to these benchmarks ensures that we are not just a supplier, but a strategic partner in your success.

Customized Solutions

Recognizing that standard components may not always meet the unique demands of every application, we offer extensive capabilities for developing customized Kragstuurbuis van hoë gehalte solutions. Our engineering team collaborates closely with clients from concept to production to deliver precisely tailored components.

Our Customization Process Includes:

- Design Consultation: Working with your engineering team to understand specific vehicle architecture, hydraulic system parameters, space constraints, and environmental exposure. This involves detailed CAD modeling and DFM (Design for Manufacturability) analysis.

- Material Specification: Recommending optimal material choices (e.g., specific steel alloys, stainless steel grades, or specialized coatings) to meet unique strength, weight, or corrosion resistance requirements.

- Complex Geometries: Producing tubes with intricate bends, multiple radii, and tight tolerances, including assemblies that integrate flexible hose sections, brackets, or vibration dampeners.

- End Fitting Configurations: Custom end forms, flares, and fitting attachments (e.g., metric, imperial, ORB, AN fittings) to ensure perfect compatibility with existing system components.

- Prototyping and Validation: Rapid prototyping capabilities for quick iteration and design validation, followed by rigorous testing (e.g., fatigue, burst, thermal cycling) to ensure the customized solution meets all performance criteria before mass production.

- Specialized Coatings and Treatments: Applying bespoke surface treatments for enhanced wear resistance, specific chemical compatibility, or aesthetic requirements.

Our flexibility in manufacturing and engineering expertise allows us to provide solutions that precisely integrate with your designs, often leading to improved performance, simplified assembly, and reduced overall system costs.

Application Case Studies (Illustrative Examples)

Below are illustrative examples demonstrating the impact of deploying a Kragstuurbuis van hoë gehalte in real-world scenarios, highlighting specific advantages and outcomes.

Case Study 1: Heavy-Duty Truck OEM

- Challenge: A major truck manufacturer faced persistent issues with premature power steering tube failures in their long-haul vehicles operating in diverse climates, leading to increased warranty claims and fleet downtime. The primary failure modes were corrosion-induced leaks and fatigue cracking near bends.

- Solution: We developed a custom power steering tube solution utilizing a specialized high-strength steel alloy with an advanced zinc-nickel coating. The design incorporated optimized bend radii and a localized vibration dampener.

- Results: After implementing our tubes, the OEM reported a 70% reduction in power steering tube-related warranty claims over a 3-year period. Field data indicated a doubling of average tube service life, significantly enhancing vehicle reliability and reducing operational costs for their customers.

Case Study 2: Agricultural Equipment Manufacturer

- Challenge: An agricultural equipment manufacturer needed power steering tubes capable of extreme vibration resistance and robust protection against corrosive agricultural chemicals and debris. Standard tubes were prone to abrasion and fatigue in critical areas.

- Solution: We provided a solution featuring stainless steel tubing (316L for enhanced chemical resistance) with a protective polymer sleeve in high-abrasion zones. Precision CNC bending minimized stress concentrations, and all connections were designed for maximum seal integrity under dynamic loads.

- Results: The new tubes demonstrated superior resistance to chemical degradation and mechanical abrasion. Vibration fatigue life improved by 50% compared to previous components. This led to fewer field service calls and improved reliability for farmers during critical harvest seasons.

These examples underscore our capability to deliver engineered solutions that address specific operational challenges, resulting in tangible benefits for our clients.

Product Specifications Table

Below are typical technical specifications for a standard Kragstuurbuis van hoë gehalte, demonstrating our commitment to robust engineering.

| Parameter | Spesifikasie | Relevant Standard/Test Method |

|---|---|---|

| Material (Tube) | Low Carbon Steel (e.g., SAE 1010/1020) or Stainless Steel (e.g., SS304/316) | ASTM A179, DIN 2391, EN 10305 |

| Operating Pressure (Max) | 150 Bar (2175 PSI) | SAE J188, DIN 73005 |

| Burst Pressure (Min) | 600 Bar (8700 PSI) – Safety Factor 4:1 | SAE J188, ISO 6605 |

| Operating Temperature Range | -40°C to +120°C | OEM Specific, ISO 6605 |

| Corrosion Resistance (Salt Spray) | >400 hours (Zinc-Nickel Coating) | ASTM B117, ISO 9227 |

| Fatigue Life (Pulsation) | >1.5 million cycles (at max operating pressure) | SAE J188, ISO 6605-4 |

| Cleanliness Level | ISO 4406: 18/16/13 (Particle Count) | ISO 4406 |

| Tube Outer Diameter (Typical) | 10mm, 12mm, 16mm (customizable) | DIN 2391, SAE J527 |

| Wall Thickness (Typical) | 1.0mm to 2.0mm (material dependent) | DIN 2391, SAE J527 |

Product Comparison: High-Quality vs. Standard Power Steering Tubes

This comparison highlights the significant differences between a Kragstuurbuis van hoë gehalte and a standard, economy-grade tube, emphasizing the value proposition of investing in superior components.

| Feature | High-Quality Tube | Standard/Economy Tube |

|---|---|---|

| Material Grade | Premium seamless steel alloys (SAE 1010/1020, SS304/316) with controlled metallurgy. | Basic ERW (Electric Resistance Welded) steel or lower-grade seamless steel. |

| Corrosion Resistance | Advanced multi-layer coatings (Zinc-Nickel, e-coat); >400-1000 hrs salt spray. | Basic zinc plating or no coating; |

| Fatigue Life (Pulsation) | Excellent; >1.5 million cycles @ max operating pressure. | Moderate; typically |

| Burst Pressure Safety Factor | High (4:1 or greater above max operating pressure). | Lower (2:1 to 3:1), closer to maximum operating pressure. |

| Manufacturing Precision | CNC bent, tight dimensional tolerances, meticulous end-forming. | Manual/semi-automatic bending, wider tolerances, less consistent end forms. |

| Internal Cleanliness | Rigorously cleaned, verified to ISO 4406 standards. | Basic cleaning, higher risk of internal contaminants. |

| Vibration Damping | Optimized routing, potential for integrated dampeners, reduced NVH. | Minimal consideration, higher NVH potential. |

| Expected Service Life | Long-term reliability, often exceeding 10 years/150,000 miles. | Shorter lifespan, potential for premature failure, typically 3-5 years. |

| Total Cost of Ownership | Lower (due to reduced failures, less downtime, fewer replacements). | Higher (due to frequent replacements, maintenance, and potential system damage). |

Frequently Asked Questions (FAQ)

Q: What makes your power steering tubes "high-quality"?

A: Our Kragstuurbuis van hoë gehalte products are distinguished by premium raw materials, precision CNC manufacturing, advanced corrosion-resistant coatings, rigorous multi-stage testing (including burst, fatigue, and salt spray), and adherence to international quality standards like ISO 9001 and IATF 16949. This ensures superior durability, leak integrity, and extended service life.

Q: Can you produce tubes for specialized or custom vehicle applications?

A: Absolutely. We specialize in customized solutions. Our engineering team works directly with clients to design, prototype, and manufacture power steering tubes tailored to specific vehicle geometries, pressure requirements, material needs, and environmental conditions. We utilize advanced CAD/CAM and finite element analysis (FEA) to optimize designs.

Q: What is the typical lead time for a new order or custom project?

A: Lead times vary based on complexity and order volume. For standard products, typical lead times range from 4-6 weeks. Custom projects, involving design, prototyping, and tooling, may range from 8-16 weeks for initial samples, followed by established production lead times. We strive for efficient scheduling and communication throughout the process.

Q: What kind of warranty do you offer on your products?

A: We stand by the quality of our products with a comprehensive warranty against manufacturing defects for a specified period, typically 1 to 2 years, or a defined mileage/hour usage, depending on the application and agreement. Specific terms will be provided with your quotation. Our commitment is to client satisfaction and product reliability.

Q: How do you ensure product cleanliness for hydraulic systems?

A: Internal cleanliness is paramount for hydraulic components. Our manufacturing process includes multiple cleaning stages, such as high-pressure flushing and ultrasonic cleaning, followed by stringent cleanliness verification using particle counting (e.g., to ISO 4406 standards). Tubes are capped and sealed immediately after cleaning to prevent re-contamination during storage and transit.

Logistics, Warranty, and After-Sales Support

We are committed to providing a seamless experience from initial inquiry to long-term product performance. Our operational framework is designed to ensure reliability and customer satisfaction.

Lead Time and Fulfillment:

- Standard Orders: Typically 4-6 weeks from order confirmation to shipment, depending on volume and current production schedule.

- Custom Orders/Prototypes: Initial prototype development and sample delivery within 8-16 weeks, followed by standard production lead times upon approval.

- Global Logistics: We leverage established freight forwarders and logistics partners to ensure timely and secure delivery worldwide. Expedited shipping options are available upon request.

- Packaging: All products are professionally packaged to prevent damage and maintain cleanliness during transit, using protective caps and robust crating where necessary.

Warranty Commitments:

We provide a robust warranty for our Kragstuurbuis van hoë gehalte products, covering manufacturing defects and material integrity for a period of 1 to 2 years, or 100,000 miles/1500 operating hours (whichever comes first), from the date of purchase. Our warranty policy is designed to instill confidence in our product's durability and performance. Specific warranty details are outlined in our sales agreements and can be provided upon request.

Customer Support and After-Sales Service:

- Dedicated Support Team: Our experienced customer support and technical teams are available to assist with inquiries, technical specifications, and post-purchase support.

- Technical Assistance: We offer expert guidance on product selection, installation best practices, and troubleshooting to ensure optimal product performance.

- Feedback and Continuous Improvement: We actively solicit customer feedback to continuously improve our products and services, fostering long-term partnerships.

Conclusion

The demand for uncompromising quality, durability, and performance in critical automotive and heavy equipment systems has never been higher. A Kragstuurbuis van hoë gehalte is not merely a component; it is an assurance of safety, operational efficiency, and long-term reliability. By investing in superior materials, advanced manufacturing processes, rigorous testing, and comprehensive technical support, we deliver products that not only meet but exceed the stringent requirements of modern industries.

Partnering with a trusted manufacturer for these vital components ensures that your systems operate at peak performance, minimize downtime, and contribute to the overall success of your operations.

References

- SAE International. (2020). J188: Power Steering Hose - High Pressure.

- SAE International. (2018). J2053: High Pressure Power Steering Tube Assemblies.

- International Organization for Standardization. (2015). ISO 9001: Quality management systems – Requirements.

- International Automotive Task Force. (2016). IATF 16949: Quality management system standard for the automotive industry.

- ASTM International. (2017). B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- International Organization for Standardization. (2011). ISO 4406: Hydraulic fluid power – Fluids – Method for coding the level of contamination by solid particles.

- International Organization for Standardization. (2014). ISO 6605-4: Hydraulic fluid power – Test methods for hoses and hose assemblies – Part 4: Impulse test with flexing in the axial direction.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNuusNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNuusNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNuusNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNuusNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNuusNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNuusNov.10,2025

High-Quality Power Steering Tubes: Durable & Leak-Proof Performance

Introduction to High-Quality Power Steering Tubes

In the intricate hydraulic systems of modern vehicles and heavy machinery, the reliability and performance of every component are paramount. Among these, the Kragstuurbuis van hoë gehalte stands as a critical conduit, responsible for the safe and efficient transfer of hydraulic fluid under extreme pressure. This component ensures smooth, responsive steering, which is vital for operational safety and driver comfort. Our focus in this document is to provide a comprehensive technical overview for B2B decision-makers and engineers, detailing the advanced engineering, rigorous manufacturing, and extensive application potential of these essential tubes.

The performance of a power steering system is directly correlated with the integrity of its tubing. Substandard tubes can lead to system failures, fluid leaks, and ultimately, costly downtime and safety hazards. Therefore, understanding the nuances of material science, manufacturing precision, and strict quality control behind superior power steering tubes is crucial for optimizing system longevity and operational efficiency.

Industry Trends in Power Steering Systems

The automotive and heavy equipment industries are undergoing significant transformations, driven by advancements in technology, stricter environmental regulations, and increasing demands for safety and efficiency. These trends directly impact the design and manufacturing of power steering components, including the Kragstuurbuis van hoë gehalte.

- Shift Towards Electrification: While Electric Power Steering (EPS) systems are gaining traction, hydraulic power steering (HPS) remains prevalent in heavy-duty vehicles, commercial trucks, and many industrial applications due to its robust nature and high force output. Even in hybrid systems, reliable hydraulic components are essential.

- Durability and Longevity: Operators demand components that can withstand harsh operating conditions, extreme temperatures, and corrosive environments. This drives the adoption of advanced materials and surface treatments for enhanced wear and corrosion resistance.

- Noise, Vibration, and Harshness (NVH) Reduction: Engineers are continually seeking ways to minimize NVH. Kragstuurbuis van hoë gehalte designs incorporate features like specialized damping elements and precision bending to mitigate fluid pulsations and structural vibrations.

- Miniaturization and Space Optimization: With increasingly crowded engine bays, there is a constant need for compact, optimized designs that maintain performance. This often involves intricate tube routing and custom bending.

- Material Science Innovations: Research into high-strength, lightweight alloys and advanced polymer coatings is ongoing, aiming to reduce overall vehicle weight, improve fuel efficiency, and extend component life.

- Stringent Safety Standards: Global regulatory bodies continue to impose stricter safety and environmental standards, necessitating robust testing and certification for all steering components.

These trends underscore the critical need for suppliers to not only meet current specifications but also to innovate and provide solutions that anticipate future industry demands for performance, reliability, and cost-effectiveness.

Technical Specifications & Materials

The performance of a Kragstuurbuis van hoë gehalte is fundamentally determined by its material composition and adherence to precise technical specifications. Our tubes are engineered to withstand the demanding conditions of hydraulic systems.

Typical Materials:

- Carbon Steel Alloys: High-strength low-alloy (HSLA) steels like SAE 1010, SAE 1020, or equivalent are commonly used for their excellent tensile strength and fatigue resistance. These are often treated with anti-corrosion coatings.

- Stainless Steel: For applications requiring superior corrosion resistance, such as those exposed to harsh chemicals or marine environments, grades like 304 or 316 stainless steel are preferred.

- Aluminum Alloys: Used in applications where weight reduction is critical, often for return lines or lower-pressure sections, offering good thermal conductivity and corrosion resistance when properly treated.

- Specialized Elastomers/Fluoropolymers: For flexible sections or hoses within the assembly, materials like EPDM, NBR, or FKM are chosen for their resilience to hydraulic fluids, temperature extremes, and chemical degradation.

Critical Technical Parameters:

- Operating Pressure: Typically ranging from 70 Bar (1000 PSI) to 150 Bar (2200 PSI) for standard systems, with burst pressures often exceeding 400 Bar (5800 PSI) to ensure a safety factor of at least 4:1.

- Temperatuurspeling: Designed to perform reliably from -40°C to +120°C, accommodating diverse operational climates and engine bay heat.

- Corrosion Resistance: Achieved through galvanization, zinc-nickel plating, or specialized organic coatings, providing over 400 hours of salt spray resistance (ASTM B117).

- Vibration Fatigue Life: Tubes must withstand millions of vibration cycles at operational frequencies without developing cracks or leaks, validated through rigorous dyno testing to SAE J188 standards.

- Internal Surface Finish: Smooth internal bore is crucial to minimize flow restriction and cavitation, ensuring optimal fluid dynamics and pump longevity.

- Bending Radius: Precision-controlled bending to meet OEM specifications without compromising tube integrity or wall thickness.

These parameters are meticulously controlled throughout the manufacturing process, ensuring that each Kragstuurbuis van hoë gehalte meets or exceeds industry benchmarks for performance and reliability.

Manufacturing Process Flow for High-Quality Power Steering Tubes

The production of a Kragstuurbuis van hoë gehalte involves a multi-stage, precision-engineered process designed to ensure structural integrity, dimensional accuracy, and optimal performance under extreme conditions. Our manufacturing adheres to stringent international standards like ISO 9001 and IATF 16949.

Process Steps:

- Material Selection and Preparation:

High-grade seamless steel tubing (e.g., SAE 1010/1020, DIN 2391/2445) or stainless steel is sourced from certified suppliers. Incoming material undergoes spectrometric analysis and mechanical testing (tensile strength, yield strength, elongation) to verify compliance with specifications.

- Tube Cutting and Deburring:

Tubes are cut to precise lengths using CNC-controlled saws or laser cutting, minimizing material waste and ensuring dimensional accuracy. Ends are meticulously deburred to prevent internal contamination and facilitate subsequent processing.

- Precision Bending (CNC Machining):

Advanced CNC tube bending machines form the tubes into complex geometries with tight tolerances. This process requires precise tooling and programming to avoid kinking, flattening, or excessive wall thinning at bends. Optical scanning ensures conformity to 3D CAD models.

- End Forming and Flaring:

Tube ends are precisely formed (e.g., flaring, swaging, beading) to create secure, leak-proof connections with hydraulic fittings. This often involves cold forming processes that enhance material strength at critical connection points.

- Brazing or Welding (for multi-component assemblies):

Where multiple tube segments or fittings need joining, automated brazing or TIG/MIG welding processes are employed. Weld integrity is verified via visual inspection, dye penetrant testing, or X-ray inspection to ensure no porosity or structural flaws.

- Cleaning and Surface Treatment:

Tubes undergo multi-stage cleaning (e.g., alkaline wash, ultrasonic cleaning, passivation for stainless steel) to remove oils, debris, and contaminants. This is followed by corrosion-resistant coatings, such as zinc-nickel plating (offering >400 hours salt spray resistance per ASTM B117) or epoxy e-coating, applied uniformly for optimal protection.

- Assembly (if applicable):

For complex assemblies, additional components like brackets, isolators, or flexible hose sections are integrated with specialized tooling.

- Rigorous Testing and Quality Control:

Every tube undergoes comprehensive testing:

- Leak Testing: 100% pneumatic pressure testing or hydrostatic pressure testing to specified burst pressures (e.g., 4x working pressure).

- Dimensional Inspection: CMM (Coordinate Measuring Machine) or optical scanning ensures all dimensions, bend angles, and end forms meet tight tolerances.

- Functional Testing: Vibration fatigue testing (SAE J188, J2053), thermal cycling, and pressure pulsation tests simulate real-world conditions to validate service life and reliability.

- Cleanliness Verification: Internal cleanliness tests to prevent contamination of hydraulic systems.

- Packaging and Delivery:

Finished tubes are carefully packaged to prevent damage and contamination during transit, often using protective caps for open ends.

This meticulous process ensures a service life often exceeding 10 years or 150,000 miles in typical automotive applications, significantly reducing maintenance needs and improving overall system reliability. Target industries include automotive OEM, heavy equipment manufacturing, and specialized industrial hydraulic systems where reliable fluid transfer is paramount.

Application Scenarios

The versatile design and robust construction of our Kragstuurbuis van hoë gehalte enable their deployment across a broad spectrum of demanding applications where hydraulic power steering is essential:

- Automotive Passenger Vehicles: Crucial for reliable power steering in sedans, SUVs, and light trucks, ensuring driver safety and comfortable handling. Our tubes meet OEM fitment and performance requirements, contributing to smooth steering response and reduced effort.

- Commercial Trucks and Buses: Essential for heavy-duty steering systems that manage significant vehicle weights and continuous operation. The high pressure and vibration resistance of our tubes extend the service life of these critical components, minimizing costly downtime for fleet operators.

- Construction and Mining Equipment: Used in excavators, loaders, bulldozers, and mining vehicles, where extreme conditions, heavy loads, and abrasive environments demand unparalleled durability and leak-proof performance. Our tubes offer exceptional corrosion resistance and high burst pressure ratings.

- Agricultural Machinery: Tractors, combines, and other farm equipment operate in challenging outdoor conditions. Our tubes provide reliable power steering performance, reducing operator fatigue and increasing productivity in demanding agricultural tasks.

- Material Handling Equipment: Forklifts, reach stackers, and industrial lifts rely on precise hydraulic steering. Our tubes contribute to the safe and efficient operation of these machines in warehouses and logistics centers.

- Specialized Industrial Hydraulic Systems: While primarily focused on power steering, the principles of high-quality fluid transfer for pressure and return lines extend to various industrial hydraulic applications where custom tube assemblies are required for energy-saving and corrosion-resistant fluid conveyance.

In each scenario, the robust design and precise manufacturing of our power steering tubes translate into enhanced operational reliability, reduced maintenance, and improved overall system efficiency.

Technical Advantages

Opting for a Kragstuurbuis van hoë gehalte provides distinct technical advantages that translate directly into superior system performance and lower total cost of ownership (TCO).

- Exceptional Pressure Resistance: Engineered to significantly exceed typical operating pressures, ensuring a substantial safety margin against burst or fatigue failures. This prevents catastrophic fluid leaks and maintains consistent steering performance under peak loads.

- Superior Corrosion Protection: Advanced multi-layer coatings (e.g., zinc-nickel, epoxy) provide unparalleled resistance to road salts, chemicals, and environmental factors. This extends component life, especially in regions with harsh weather or in industrial settings. Our coatings often surpass 1000 hours of salt spray resistance for specific applications, greatly exceeding standard requirements.

- Optimized Vibration Damping: Precision bending and optional integrated damping elements (such as resonance dampeners) are designed to absorb system vibrations and fluid pulsations. This reduces NVH (Noise, Vibration, and Harshness), enhancing driver comfort and preventing premature wear on pumps and racks.

- Enhanced Material Durability: Utilization of high-strength steel alloys or robust stainless steel, combined with meticulous heat treatments, provides excellent fatigue resistance and structural integrity over millions of operational cycles. This translates into a significantly longer service life compared to standard alternatives.

- Precision Dimensional Accuracy: Manufactured with tight tolerances using CNC technology, ensuring perfect fitment and seamless integration with existing hydraulic systems. This eliminates installation issues and potential leak points.

- Leak-Proof Connections: Advanced end-forming techniques (e.g., precise flaring, double-flaring, or O-ring boss connections) create robust, leak-free seals when properly installed with compatible fittings, critical for maintaining hydraulic system integrity and fluid levels.

- High Internal Cleanliness: Tubes are thoroughly cleaned to remove manufacturing residues, preventing contamination of the hydraulic fluid. This protects sensitive components like steering pumps and valves from abrasive wear, extending the life of the entire power steering system.

These advantages collectively contribute to a more reliable, durable, and safer power steering system, directly impacting vehicle uptime and operational costs.

Vendor Comparison: Key Selection Criteria

Selecting the right vendor for Kragstuurbuis van hoë gehalte is a strategic decision that impacts product reliability, supply chain efficiency, and overall cost-effectiveness. Here are critical factors to consider when evaluating potential suppliers:

- Certifications and Compliance:

A reputable vendor should possess certifications such as ISO 9001 (Quality Management Systems), IATF 16949 (Automotive Quality Management System), and demonstrate compliance with relevant industry standards (e.g., SAE J188, ASTM, DIN). This guarantees adherence to strict quality protocols.

- Manufacturing Capabilities and Technology:

Assess the vendor's infrastructure, including advanced CNC tube bending, automated welding/brazing, and specialized coating facilities. Look for evidence of investment in modern machinery and lean manufacturing principles.

- Quality Control and Testing Regimen:

Inquire about their in-house testing capabilities, including hydrostatic burst testing, pulsation fatigue testing, salt spray corrosion testing, and dimensional inspection (CMM). A robust QC process with documented procedures is crucial.

- Material Sourcing and Traceability:

Ensure the vendor uses only high-grade, traceable raw materials from approved suppliers. Transparency in material certification and origin is vital for product integrity.

- Engineering and Design Support:

A strong vendor offers design collaboration, prototyping services, and the ability to reverse-engineer components or develop custom solutions based on specific OEM requirements. Their engineering team should be proficient in CAD/CAM software.

- Lead Times and Supply Chain Reliability:

Evaluate their capacity to meet production volumes, on-time delivery rates, and contingency plans for supply chain disruptions. Flexibility for urgent orders or design changes is a significant asset.

- Customer Support and Warranty:

Responsive customer service, clear warranty terms, and accessible after-sales support are indicative of a reliable long-term partner.

- Cost-Effectiveness vs. Price:

While price is a factor, focus on overall value, considering product quality, longevity, and the potential for reduced warranty claims or operational downtime. A slightly higher upfront cost for a truly high-quality component often yields significant savings over its lifecycle.

Our commitment to these benchmarks ensures that we are not just a supplier, but a strategic partner in your success.

Customized Solutions

Recognizing that standard components may not always meet the unique demands of every application, we offer extensive capabilities for developing customized Kragstuurbuis van hoë gehalte solutions. Our engineering team collaborates closely with clients from concept to production to deliver precisely tailored components.

Our Customization Process Includes:

- Design Consultation: Working with your engineering team to understand specific vehicle architecture, hydraulic system parameters, space constraints, and environmental exposure. This involves detailed CAD modeling and DFM (Design for Manufacturability) analysis.

- Material Specification: Recommending optimal material choices (e.g., specific steel alloys, stainless steel grades, or specialized coatings) to meet unique strength, weight, or corrosion resistance requirements.

- Complex Geometries: Producing tubes with intricate bends, multiple radii, and tight tolerances, including assemblies that integrate flexible hose sections, brackets, or vibration dampeners.

- End Fitting Configurations: Custom end forms, flares, and fitting attachments (e.g., metric, imperial, ORB, AN fittings) to ensure perfect compatibility with existing system components.

- Prototyping and Validation: Rapid prototyping capabilities for quick iteration and design validation, followed by rigorous testing (e.g., fatigue, burst, thermal cycling) to ensure the customized solution meets all performance criteria before mass production.

- Specialized Coatings and Treatments: Applying bespoke surface treatments for enhanced wear resistance, specific chemical compatibility, or aesthetic requirements.

Our flexibility in manufacturing and engineering expertise allows us to provide solutions that precisely integrate with your designs, often leading to improved performance, simplified assembly, and reduced overall system costs.

Application Case Studies (Illustrative Examples)

Below are illustrative examples demonstrating the impact of deploying a Kragstuurbuis van hoë gehalte in real-world scenarios, highlighting specific advantages and outcomes.

Case Study 1: Heavy-Duty Truck OEM

- Challenge: A major truck manufacturer faced persistent issues with premature power steering tube failures in their long-haul vehicles operating in diverse climates, leading to increased warranty claims and fleet downtime. The primary failure modes were corrosion-induced leaks and fatigue cracking near bends.

- Solution: We developed a custom power steering tube solution utilizing a specialized high-strength steel alloy with an advanced zinc-nickel coating. The design incorporated optimized bend radii and a localized vibration dampener.

- Results: After implementing our tubes, the OEM reported a 70% reduction in power steering tube-related warranty claims over a 3-year period. Field data indicated a doubling of average tube service life, significantly enhancing vehicle reliability and reducing operational costs for their customers.

Case Study 2: Agricultural Equipment Manufacturer

- Challenge: An agricultural equipment manufacturer needed power steering tubes capable of extreme vibration resistance and robust protection against corrosive agricultural chemicals and debris. Standard tubes were prone to abrasion and fatigue in critical areas.

- Solution: We provided a solution featuring stainless steel tubing (316L for enhanced chemical resistance) with a protective polymer sleeve in high-abrasion zones. Precision CNC bending minimized stress concentrations, and all connections were designed for maximum seal integrity under dynamic loads.

- Results: The new tubes demonstrated superior resistance to chemical degradation and mechanical abrasion. Vibration fatigue life improved by 50% compared to previous components. This led to fewer field service calls and improved reliability for farmers during critical harvest seasons.

These examples underscore our capability to deliver engineered solutions that address specific operational challenges, resulting in tangible benefits for our clients.

Product Specifications Table

Below are typical technical specifications for a standard Kragstuurbuis van hoë gehalte, demonstrating our commitment to robust engineering.

| Parameter | Spesifikasie | Relevant Standard/Test Method |

|---|---|---|

| Material (Tube) | Low Carbon Steel (e.g., SAE 1010/1020) or Stainless Steel (e.g., SS304/316) | ASTM A179, DIN 2391, EN 10305 |

| Operating Pressure (Max) | 150 Bar (2175 PSI) | SAE J188, DIN 73005 |

| Burst Pressure (Min) | 600 Bar (8700 PSI) – Safety Factor 4:1 | SAE J188, ISO 6605 |

| Operating Temperature Range | -40°C to +120°C | OEM Specific, ISO 6605 |

| Corrosion Resistance (Salt Spray) | >400 hours (Zinc-Nickel Coating) | ASTM B117, ISO 9227 |

| Fatigue Life (Pulsation) | >1.5 million cycles (at max operating pressure) | SAE J188, ISO 6605-4 |

| Cleanliness Level | ISO 4406: 18/16/13 (Particle Count) | ISO 4406 |

| Tube Outer Diameter (Typical) | 10mm, 12mm, 16mm (customizable) | DIN 2391, SAE J527 |

| Wall Thickness (Typical) | 1.0mm to 2.0mm (material dependent) | DIN 2391, SAE J527 |

Product Comparison: High-Quality vs. Standard Power Steering Tubes

This comparison highlights the significant differences between a Kragstuurbuis van hoë gehalte and a standard, economy-grade tube, emphasizing the value proposition of investing in superior components.

| Feature | High-Quality Tube | Standard/Economy Tube |

|---|---|---|

| Material Grade | Premium seamless steel alloys (SAE 1010/1020, SS304/316) with controlled metallurgy. | Basic ERW (Electric Resistance Welded) steel or lower-grade seamless steel. |

| Corrosion Resistance | Advanced multi-layer coatings (Zinc-Nickel, e-coat); >400-1000 hrs salt spray. | Basic zinc plating or no coating; <96-240 hrs salt spray. |

| Fatigue Life (Pulsation) | Excellent; >1.5 million cycles @ max operating pressure. | Moderate; typically <500,000 cycles. |

| Burst Pressure Safety Factor | High (4:1 or greater above max operating pressure). | Lower (2:1 to 3:1), closer to maximum operating pressure. |

| Manufacturing Precision | CNC bent, tight dimensional tolerances, meticulous end-forming. | Manual/semi-automatic bending, wider tolerances, less consistent end forms. |

| Internal Cleanliness | Rigorously cleaned, verified to ISO 4406 standards. | Basic cleaning, higher risk of internal contaminants. |

| Vibration Damping | Optimized routing, potential for integrated dampeners, reduced NVH. | Minimal consideration, higher NVH potential. |

| Expected Service Life | Long-term reliability, often exceeding 10 years/150,000 miles. | Shorter lifespan, potential for premature failure, typically 3-5 years. |

| Total Cost of Ownership | Lower (due to reduced failures, less downtime, fewer replacements). | Higher (due to frequent replacements, maintenance, and potential system damage). |

Frequently Asked Questions (FAQ)

Q: What makes your power steering tubes "high-quality"?

A: Our Kragstuurbuis van hoë gehalte products are distinguished by premium raw materials, precision CNC manufacturing, advanced corrosion-resistant coatings, rigorous multi-stage testing (including burst, fatigue, and salt spray), and adherence to international quality standards like ISO 9001 and IATF 16949. This ensures superior durability, leak integrity, and extended service life.

Q: Can you produce tubes for specialized or custom vehicle applications?

A: Absolutely. We specialize in customized solutions. Our engineering team works directly with clients to design, prototype, and manufacture power steering tubes tailored to specific vehicle geometries, pressure requirements, material needs, and environmental conditions. We utilize advanced CAD/CAM and finite element analysis (FEA) to optimize designs.

Q: What is the typical lead time for a new order or custom project?

A: Lead times vary based on complexity and order volume. For standard products, typical lead times range from 4-6 weeks. Custom projects, involving design, prototyping, and tooling, may range from 8-16 weeks for initial samples, followed by established production lead times. We strive for efficient scheduling and communication throughout the process.

Q: What kind of warranty do you offer on your products?

A: We stand by the quality of our products with a comprehensive warranty against manufacturing defects for a specified period, typically 1 to 2 years, or a defined mileage/hour usage, depending on the application and agreement. Specific terms will be provided with your quotation. Our commitment is to client satisfaction and product reliability.

Q: How do you ensure product cleanliness for hydraulic systems?

A: Internal cleanliness is paramount for hydraulic components. Our manufacturing process includes multiple cleaning stages, such as high-pressure flushing and ultrasonic cleaning, followed by stringent cleanliness verification using particle counting (e.g., to ISO 4406 standards). Tubes are capped and sealed immediately after cleaning to prevent re-contamination during storage and transit.

Logistics, Warranty, and After-Sales Support

We are committed to providing a seamless experience from initial inquiry to long-term product performance. Our operational framework is designed to ensure reliability and customer satisfaction.

Lead Time and Fulfillment:

- Standard Orders: Typically 4-6 weeks from order confirmation to shipment, depending on volume and current production schedule.

- Custom Orders/Prototypes: Initial prototype development and sample delivery within 8-16 weeks, followed by standard production lead times upon approval.

- Global Logistics: We leverage established freight forwarders and logistics partners to ensure timely and secure delivery worldwide. Expedited shipping options are available upon request.

- Packaging: All products are professionally packaged to prevent damage and maintain cleanliness during transit, using protective caps and robust crating where necessary.

Warranty Commitments:

We provide a robust warranty for our Kragstuurbuis van hoë gehalte products, covering manufacturing defects and material integrity for a period of 1 to 2 years, or 100,000 miles/1500 operating hours (whichever comes first), from the date of purchase. Our warranty policy is designed to instill confidence in our product's durability and performance. Specific warranty details are outlined in our sales agreements and can be provided upon request.

Customer Support and After-Sales Service:

- Dedicated Support Team: Our experienced customer support and technical teams are available to assist with inquiries, technical specifications, and post-purchase support.

- Technical Assistance: We offer expert guidance on product selection, installation best practices, and troubleshooting to ensure optimal product performance.

- Feedback and Continuous Improvement: We actively solicit customer feedback to continuously improve our products and services, fostering long-term partnerships.

Conclusion

The demand for uncompromising quality, durability, and performance in critical automotive and heavy equipment systems has never been higher. A Kragstuurbuis van hoë gehalte is not merely a component; it is an assurance of safety, operational efficiency, and long-term reliability. By investing in superior materials, advanced manufacturing processes, rigorous testing, and comprehensive technical support, we deliver products that not only meet but exceed the stringent requirements of modern industries.

Partnering with a trusted manufacturer for these vital components ensures that your systems operate at peak performance, minimize downtime, and contribute to the overall success of your operations.

References

- SAE International. (2020). J188: Power Steering Hose - High Pressure.

- SAE International. (2018). J2053: High Pressure Power Steering Tube Assemblies.

- International Organization for Standardization. (2015). ISO 9001: Quality management systems – Requirements.

- International Automotive Task Force. (2016). IATF 16949: Quality management system standard for the automotive industry.

- ASTM International. (2017). B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- International Organization for Standardization. (2011). ISO 4406: Hydraulic fluid power – Fluids – Method for coding the level of contamination by solid particles.

- International Organization for Standardization. (2014). ISO 6605-4: Hydraulic fluid power – Test methods for hoses and hose assemblies – Part 4: Impulse test with flexing in the axial direction.

-

Quick Release Ball Joint – Tool-Free, Durable, Leak-TightNuusNov.13,2025

-

Spiral Guard Hose Protection — Durable, UV-Resistant WrapNuusNov.13,2025

-

SAE J1401 Brake Hose Specifications: Durable, Low ExpansionNuusNov.13,2025

-

SAE J1401 Brake Hose Specifications | DOT-Approved, DurableNuusNov.13,2025

-

Spiral Guard Hose Protection - Abrasion-Resistant, UV-StableNuusNov.10,2025

-

SAE J1401 Brake Hose Specifications | DOT-Certified, DurableNuusNov.10,2025